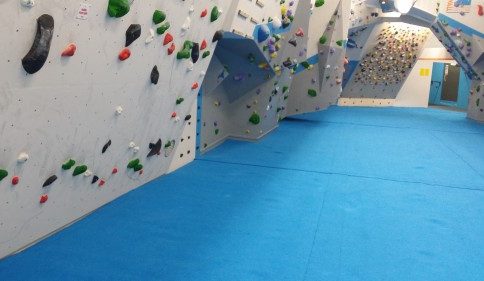

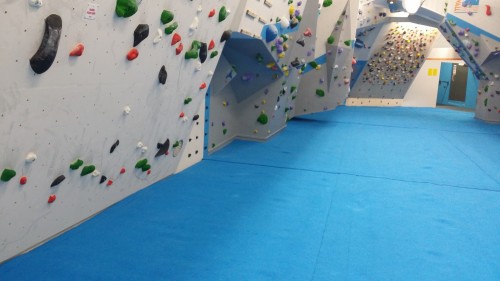

Our team were asked to design a bespoke cooling and ventilation system for an indoor climbing centre, which was being fitted out in an original archway building under a railway line. Natural light and ventilation were limited due to the nature of the building.

The design team had to engineer a bespoke solution that was sympathetic to the clients budget whilst being fit for purpose. There were a few issues to consider given we were unable to fix to the archway structure, change the look of the frontage (due to planning constraints) and did not have the luxury of an external roof or wall to site plant upon. These are the type of bespoke solutions we are exceptionally good at, and not too many companies are able to offer this level of expertise.

We needed to ensure that sufficient fresh air would be mechanically supplied into the space for the climbers comfort and to meet legislation whilst keeping them cool at all times. The client has much experience in this area and had concerns regarding airborne chalk particles contaminating the environment. We went to work in producing a solution which ticked all of the boxes.

When we started the project, the fit out of the centre was well underway and nearing completion, so speedy installation of ducts and equipment was of paramount importance. With the support of the clients fit out team this went smoothly and we managed to vacate the climbing area ahead of the grand opening.

Air Options designed, procured and installed a Hitachi RAS10 heat pump system utilising an internally mounted condensing unit and a fan coil linked to a textile sock. This eliminated the need for external plant space given the air exchange was carried out via hidden grilles to the shop front, having no aesthetic impact at all.

Fresh air, is filtered and heated, and supplied into the climbing area via bulls eye diffuser mixing with the return air. This was aesthetically pleasing and most importantly effective in delivering the air to where it’s required quietly and efficiently. The extract system was designed to remove air at low level due to the chalk contaminants. The air is filtered ahead of recirculation via pre and bag filters requiring minimal maintenance. To finish with the system was balanced so that the extraction, fresh air make up and heat pump system worked in harmony keeping running costs to a minimum.

All in all the system looks great, came in on budget without variation, works extremely well and we have another very happy customer. We love these type of projects and they deviate away from the normal commercial style installation and allow us to demonstrate what is truly possible if the client and design team work as one.

Well done to everyone involved and congratulations to our client in opening yet another great climbing centre.